Intelligent Current Control

Make solid welds with a long stick-out in narrow gaps.

Intelligent Current Control for Sigma Select

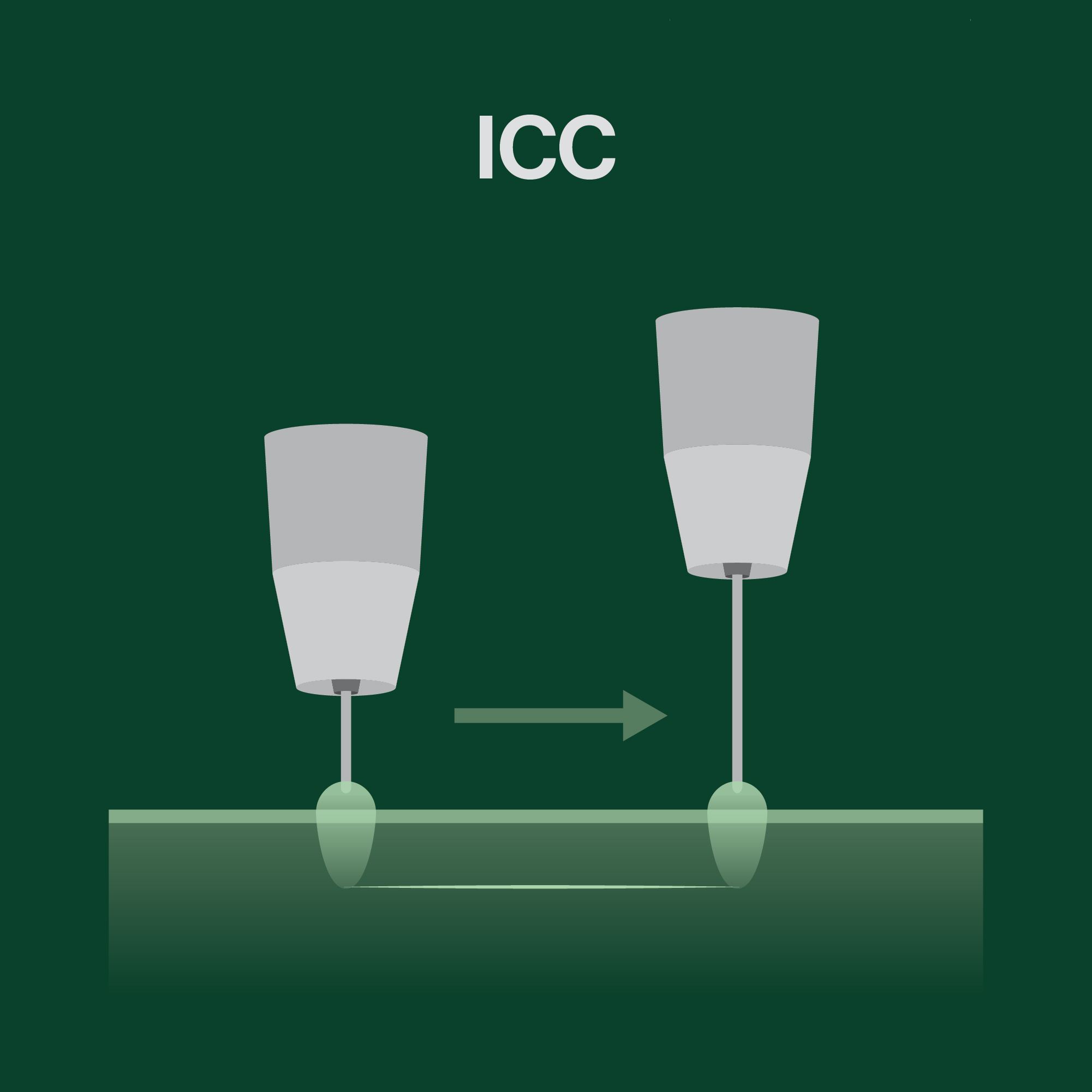

The MIG/MAG function Intelligent Current Control (ICC) makes any welder able to weld with varying stick-out and still achieve high quality and penetration. This allows you to reduce the groove angle size in your workpieces, resulting in fewer welds needed to fill the gap.

Benefits

- Improved weld quality because of the heat-input is not affected by changes in stick-out.

- Fewer weld seams are requires to fill the groove, which reduces the time spent per weld.

- Three times faster filling of grooves compared to using MMA (stick) welding.

- Reduced amount of filler material leads to cost savings on consumables.

- Use the same MIG welding machine for both the root pass and additional layers.

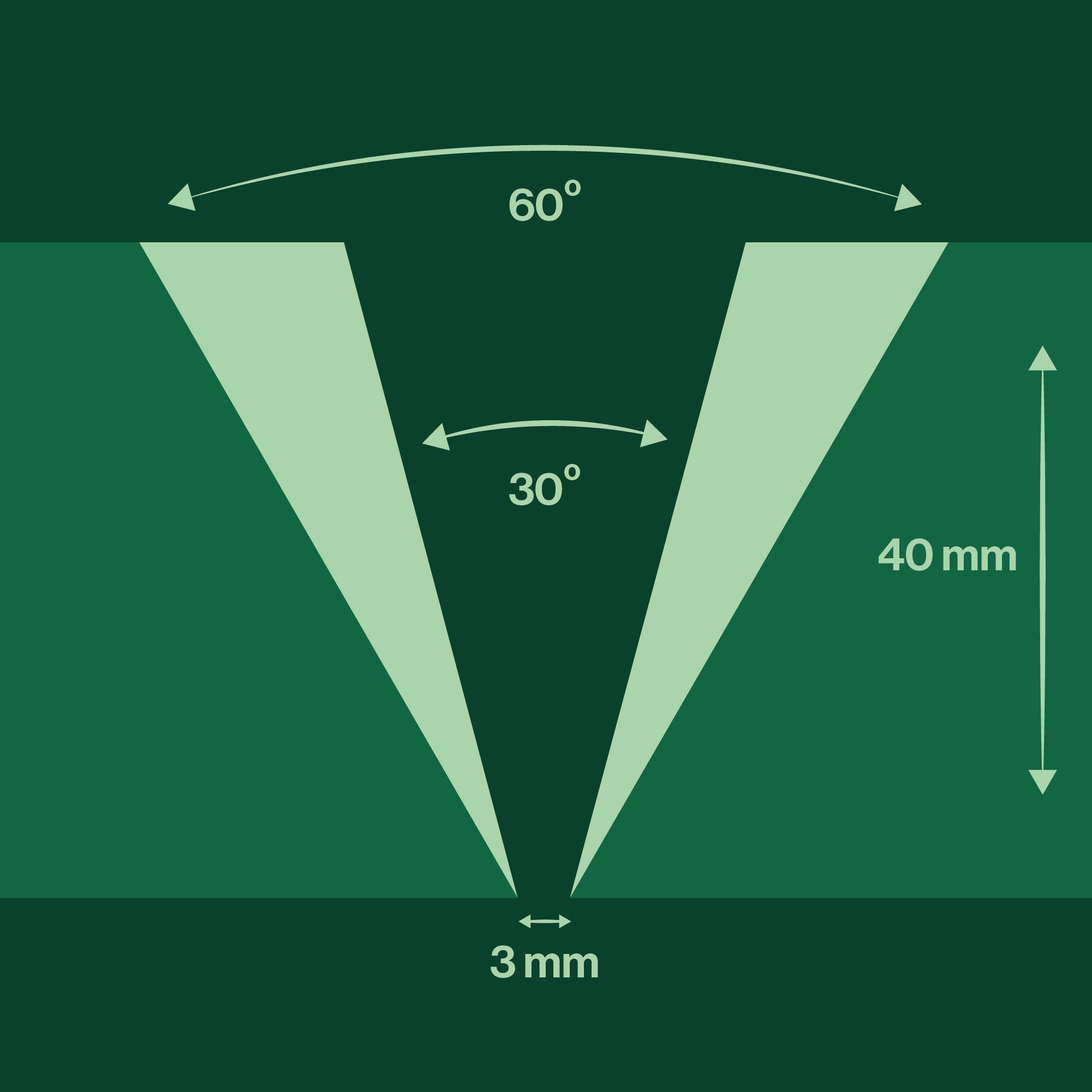

Reduce the groove angle size

With ICC, you can maintain the arc pressure and current flow even with a long stick-out and achieve optimal penetration.With ICC, it is possible to reduce the groove angle size on your plates to 30°.

This allows you to still achieve a perfect root pass while reducing the number of filler layers. As a result, costs for consumables are reduced, and valuable time is saved in the production.

ICC is ideal for

- Multipass welding with narrow gaps.

- Root passes.

- Thick materials.

- All welding positions.

- Mild steel.

- Manual and automated welding.

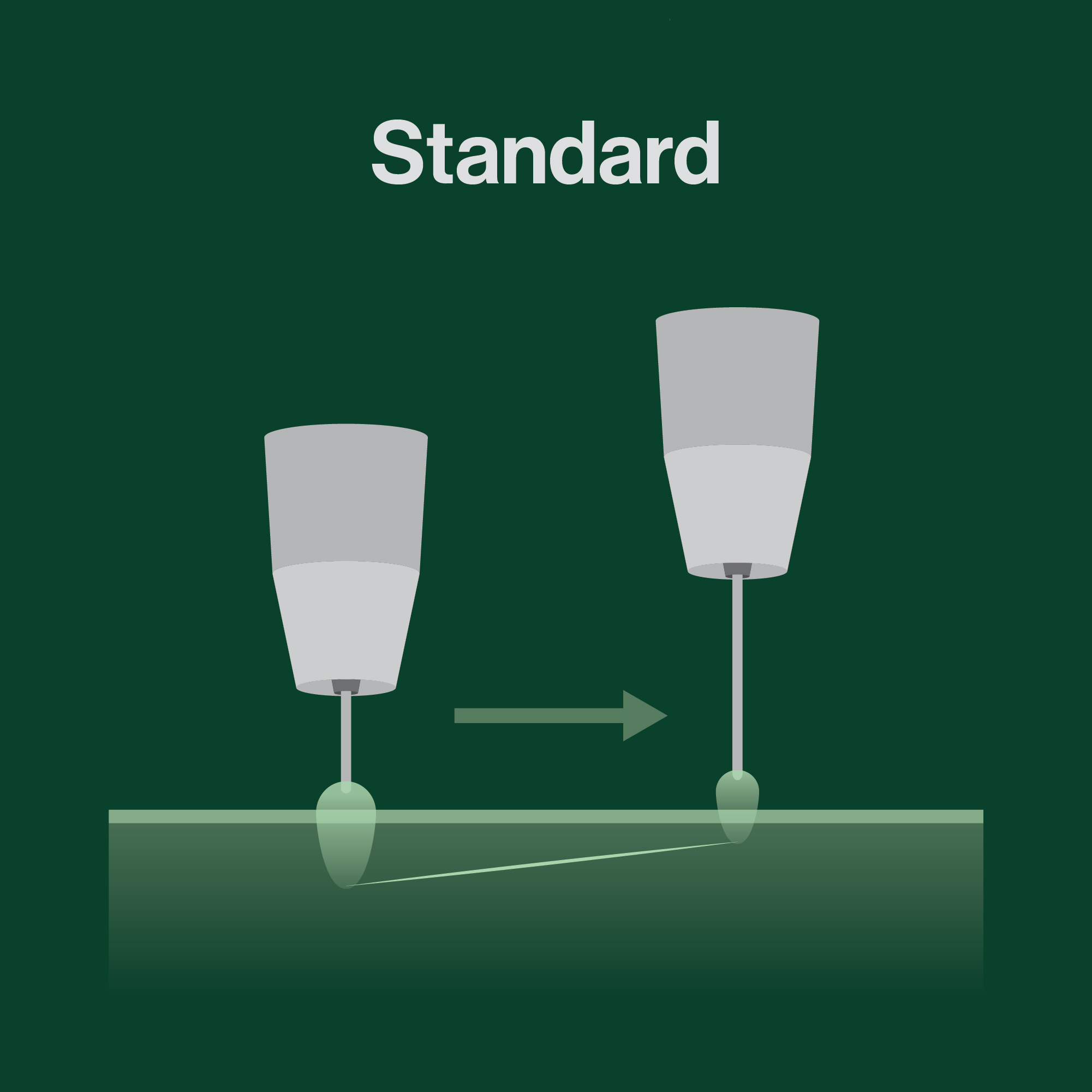

What you set is what you get

Normally, the set welding current determines the desired current intensity. Varying stick-out affects resistance and, consequently, the electrical current intensity. This variation leads to changes in the delivered current.

With ICC, the set welding current remains constant throughout the welding process for stick-out lenghts up to 40 mm. What you set on the control panel is what you get.

Stable current flow and penetration

When using standard DC welding and a short stick-out, the stability of the arc is prefect. However, with a long stick-out, the arc pressure decreases, resulting in an unstable arc and inadequate penetration.

With ICC, you can maintain the arc pressure and current flow even with a long stick-out and achieve optimal penetration.

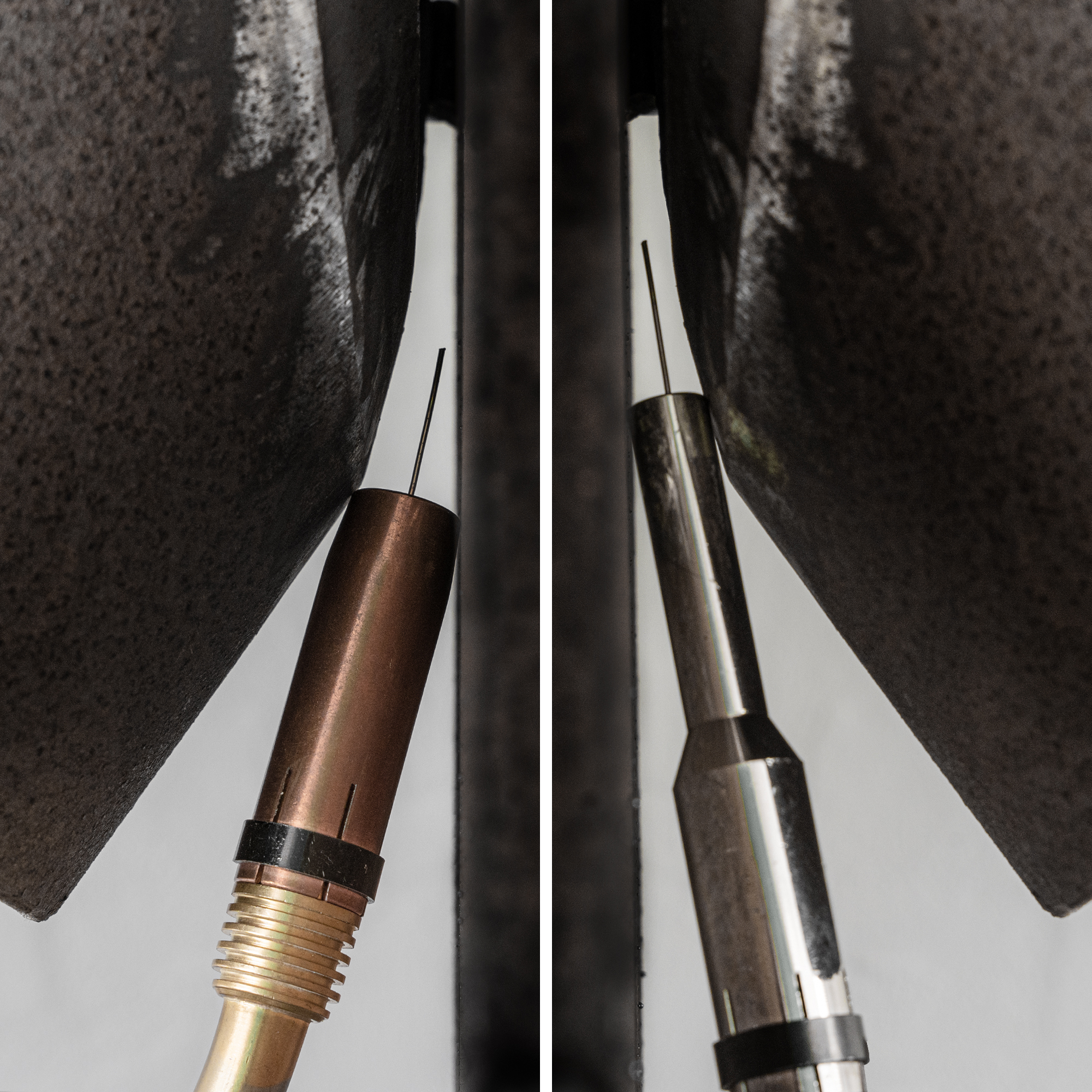

Slim gas nozzle for narrow gap welding

Choose a slim gas nozzle and contact tip for your torch to maintain the same focused arc as with regular DC welding. Use it for the root pass and the first few layers in your narrow gap weld. The slim shape makes you able to reach even further. Switch back to a regular gas nozzle when necessary to ensure optimal gas protection.